Technical details: Single-roller burnishing tool modular

Modular single-roller burnishing tool for external use

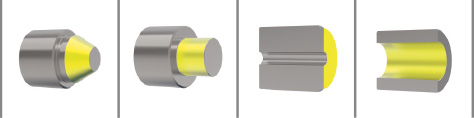

| Application | cylindrical shafts also against shoulder (one roll in use at a time) |

| Diameter range (Ø) |

from 15mm |

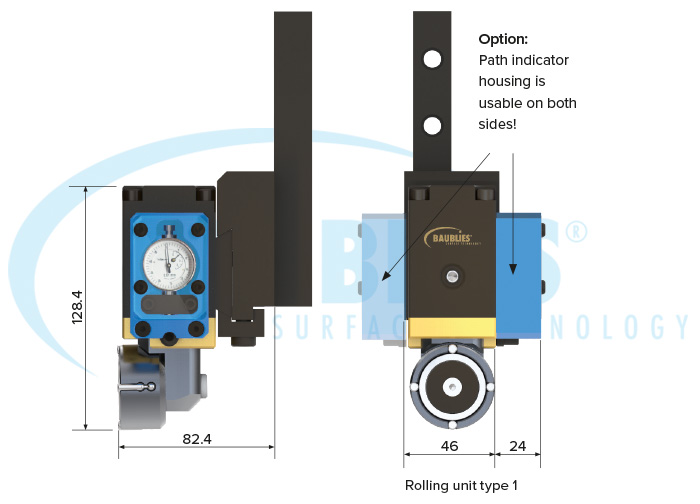

Options

- Fixtures VDI, HSK etc.

- Path indicator housing, usable on both sides

Application parameters

Please note that this information represents standard values which must be adapted to the individual cases.

| Speed | up to 200 m/min |

| Feed rate | up to 1 mm/U |

| Workpiece allowance | up to 0.02 mm |

| Tool preload | up to 1.2 mm |

| Lubrication | emulsion or oil; filtration of the lubricant (< 40 μm) can improve the surface quality and the tool life |

| Pre-machining of workpiece | surface roughness up to 15 μm |

| Workpiece hardness | 45 HRC |

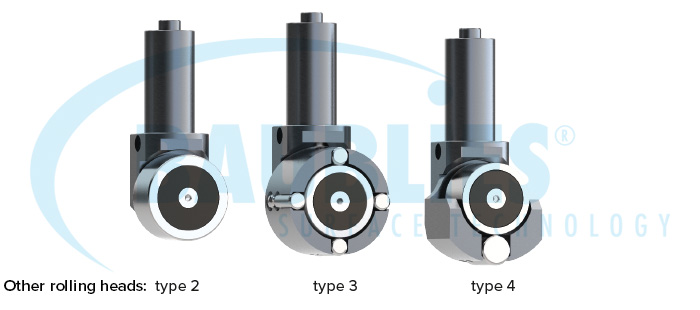

Modular single-roller burnishing tool system

Rolling unit for smoothening and work hardening shafts. Processing cylindrical shafts also against shoulder.

ADVANTAGES

- Easy to use

- Easy exchangeable pressure spring

- Rugged tool design

- Slim design

- Fast feedrate possible

- Low wear part costs

- High surface quality > Rz 1

TIP

The occuring forces can be very high! For safety reasons always ensure a sufficient clamping of the workpiece and tool on your machine.

You require further information about this specific tool?

Please contact us or send us an e-mail. We will gladly inform you about further details on our tools.

Phone: +49 (0)7159 92 87-90