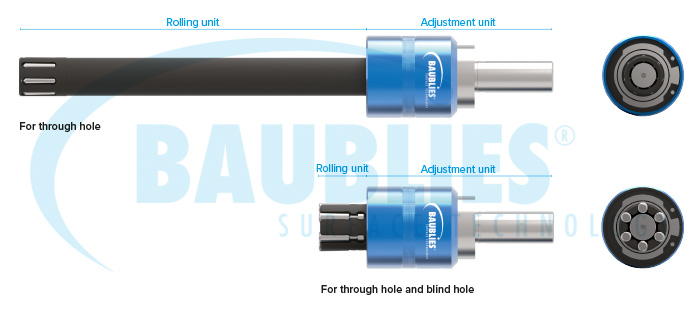

Technical Details: Data sheet internal roller burnishing tool for through hole

Internal roller burnishing IRG-Special for through hole

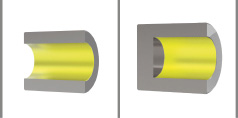

| Application | through hole |

| Fixture | as required |

| Rolling depth | as required |

| Diameter range | from 4 mm |

Options

- Internal coolant

- Different numbers of rollers

Application parameters

Please note that this information represents standard values which must be adapted to the individual cases.

| Workpiece allowance | up to 0.02 mm |

| Tool preclamping | up to 0.05 mm |

| Rotation direction of tool | ClockWise (M3) |

| Return traverse | always in rapid traverse (GO) |

| Lubrication | emulsion or oil; filtration of the lubricant (<40 μm) can improve the surface quality and the tool life |

| Pre-machining of workpiece | surface roughness (Rz) up to 12 μm tolerance IT8 or better |

| Workpiece hardness | up to 45HRC |

You require further information about this specific tool?

Please contact us or send us an e-mail. We will gladly inform you about further details on our tools:

Quickrequest: "Data sheet internal roller burnishing tool for through hole"Internal roller burnishing tools in the design for through holes, with a machining length exceeding the standard, are suitable for use on virtually all common machines, e.g. lathe machines, both conventional and CNC machines.

ADVANTAGES

- very short machining time

- surface finishes of the heighest quality

- high productivity

- both workpiece or tool can be driven

- fast return of invest

- easy to maintain

- slim design

- usable on all common machines

(no special machine required)