Technical Details: Data sheet tailormade multi-roller burnishing tools small design

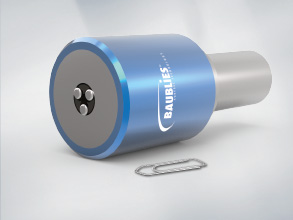

External roller burnishing tool PICCOLINO

| Application | shaft against collar | ||||||||||||||||

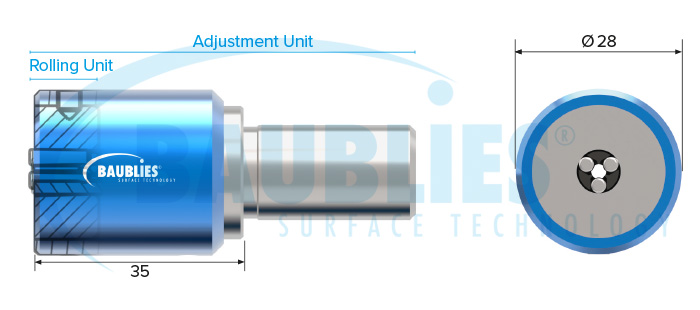

| Diameter range (Ø) | 1.0 - 7.9 mm | ||||||||||||||||

| Adjustment range |

-0.2 up to +0.1 mm | ||||||||||||||||

| Rolling depth | 40 mm | ||||||||||||||||

| Rollers |

|

||||||||||||||||

| Standard fixture | cylindrical shank Ø 6 - 22 mm Morse taper 1 to 3 |

Options

- Tailor made fixtures with clamping surface; VDI, HSK etc.

- Rolling depth unlimited with cylindrical shank

- Different number of rollers

- Tailor made rollers

- Internal coolant max. 8 bar coolant pressure

Application parameters

Please note that this information represents standard values which must be adapted to the individual cases.

| Workpiece allowance | up to 0.01 mm |

| Tool preload | up to 0.04 mm |

| Rotation direction of tool | clockwise (M3) |

| Return traverse | always in rapid traverse (G0) |

| Lubrication | emulsion or oil; filtration of the lubricant (<40 μm) can improve the surface quality and the tool life |

| Pre-machining of workpiece | surface roughness (Rz) up to 15 μm tolerance IT8 or better |

| Workpiece hardness | up to 45 HRC |

You require further information about this specific tool?

Please contact us or send us an e-mail. We will gladly inform you about further details on our tools.

Phone: +49 (0)7159 92 87-90

When setting the tool diameter below the nominal size of the tool then the taper will overlap the cage. Therefore the dimension “X” (see overleaf) will increase. This increase will be about 0.2 mm per 0.01 mm diameter enlargement (one mark on the tool scale) of the tool setting.

Tool adjustment

Further information on speed and feed rate can be found under www.baublies.com.

One mark on the tool scale 0.01 mm.

PICCOLINO external roller burnishing tools are a particularly compact design for use on machines with limited working space, such as multi-spindle and Swiss-type lathes or rotary transfer machines.

ADVANTAGES

- Very short machining time

- Surface finishes of the highest quality

- High productivity

- Workpiece is not subjected to lateral forces

- Both workpiece or tool can be driven

- Fast return of investment

- Slim design

- Usable on all common machines

(no special machine required)

Tip When setting up a tool, the revolution speed can be considerably reduced, however the feed rate per revolution is not to be decreased. When conducting roller burnishing under unfavorable conditions, e.g. when using high-strength materials with insufficient lubrication or very deep holes, it is advisable to reduce the revolution speed.