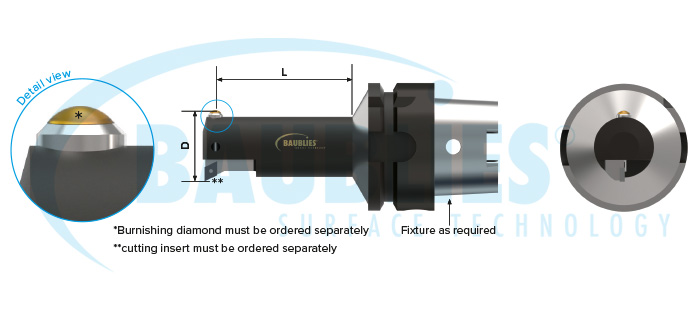

Technical details: Combination Tool, cutting / diamond burnishing

Combination Tool, cutting / diamond burnishing

| Application | Forming of internal contours by machining and diamond smoothing with one tool |

Options

- Tailor made fixtures VDI, HSK etc.

Application parameters

Please note that this information represents standard values which must be adapted to the individual cases.

| Speed | up to 150 m/min |

| Feed rate | 0.05 — 0.15 mm/rev |

| Workpiece allowance | up to 0.01 mm |

| Lubrication | emulsion or oil; filtration of the lubricant (< 40 μm) can improve the surface quality and the tool life |

| Pre-machining of workpiece | surface roughness (Rz) up to 15 μm |

Suitable for hard machining

Combination tool, cutting / diamond burnishing

Combination diamond burnishing tools for cutting and smoothening contours in one cycle: At first the geometry is produced by the cutting edge and then this surface gets burnished by the diamond. This rotating tool is usually used together with an U-axis.

ADVANTAGES

- Suitable for hard machining and thin walled workpieces

- Economic complete machining in two steps

- Changeable diamond insert

- Regrinding of the diamond is possible

You require further information about this specific tool?

Please contact us or send us an e-mail. We will gladly inform you about further details on our tools.

Phone: +49 (0)7159 92 87-90